Anybody concerned within the mining business is aware of it’s a posh subject of excessive stakes and vital challenges. In response to a latest Deloitte report, mines at this time face immense resistance to alter as a result of they depend on legacy expertise.

This hampers mining operations’ capability to face extra evermore difficult situations as they’re pressured to go deeper and additional in quest of sources.

It ought to come as no shock, then, based on the identical research, that mining productiveness continues to say no throughout the board. To make issues worse, the business as a complete is going through risky commodity costs, altering workforce demographics, and the maturation of current websites.

The excellent news is that Synthetic intelligence and machine studying algorithms can probably change the business’s trajectory. Together with IoT gadgets and massive information, clever techniques can drastically enhance mining organizations’ capability to course of, manipulate, deal with, and analyze data to:

- Uncover mining alternatives

- Plan mining operations

- Enhance effectivity and productiveness

- Implement stricter high quality management

- Enhance employee security

- Decrease the chance of human error

- Make operations extra resilient and agile

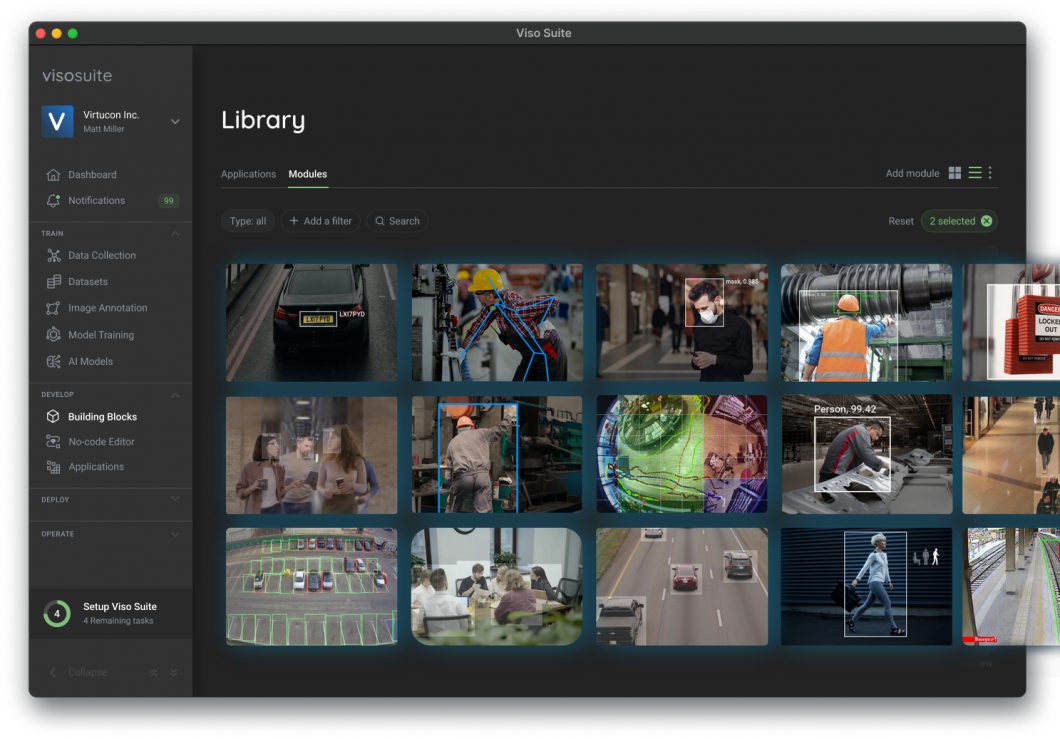

About us: Viso Suite is the end-to-end laptop imaginative and prescient infrastructure for enterprises. Viso Suite locations management of your complete utility lifecycle within the arms of ML groups from improvement to deployment to safety and past. To find out how Viso Suite can automate your small business processes, e-book a demo with our group.

Utility 1: Exploration and Concentrating on

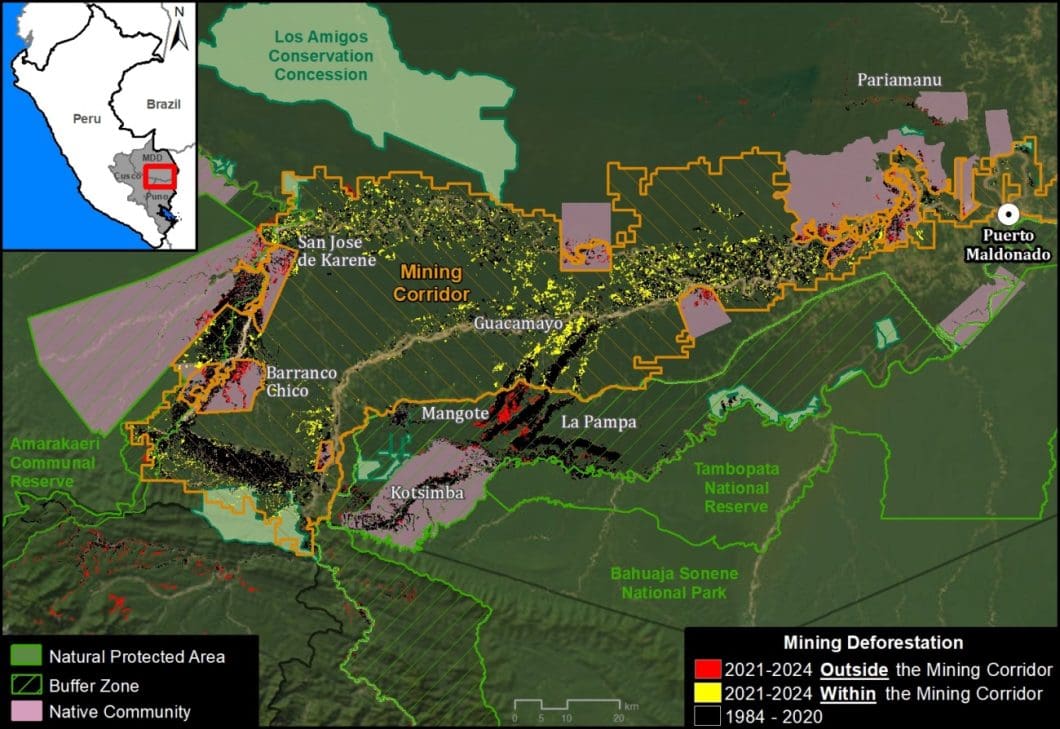

As talked about, one of many key challenges for the mining business at this time is discovering probably profitable websites. This requires accumulating, managing, and analyzing huge quantities of knowledge, one thing that AI and ML applied sciences excel at. Mines already use this method to extend the possibility of discovering new deposits and proactively cut back the environmental influence.

AI fashions can course of huge quantities of geological information a lot sooner than human surveyors. Because the expertise evolves, the hole by way of velocity and accuracy additionally continues to develop.

There are 4 primary methods through which these techniques can assist mining operations:

- Establish and recommend potential exploration targets

- Estimate a goal’s potential worth

- Establish potential environmental issues

- Generate optimized methods for deeper exploration

On the similar time, AI methods can assist rule out non-viable leads, which can lead to pointless excessive testing prices and make exploration extra environment friendly.

The pure evolution of AI exploration is that of automated exploratory drilling. These techniques use AI to pinpoint the placement of mineable sources inside goal websites, conduct preliminary exploratory drilling, and analyze the information to gauge its potential with better accuracy and estimate successive drilling areas.

Whereas nonetheless principally in an experimental stage, this will likely assist mines transition to totally autonomous exploration by focusing on new websites and conducting on-site checks utilizing distant, AI-powered tools.

Utility 2: Automated Drillers and Clever Drilling Methods

For any mining operation, drilling and blasting are two indispensable processes that happen every day. Sadly, additionally they occur to be a number of the most harmful.

It sometimes entails an iterative means of drillers creating holes in onerous surfaces. These holes are crammed with explosives to blast open even bigger holes or create cracks within the inside geology in preparation for a mining website.

Drilling patterns are rigorously deliberate primarily based on the traits of the positioning and its objective. AI and ML techniques can assist within the planning of optimum drilling patterns in addition to automate the method. This data can be utilized to configure and deploy automated drillers that comply with a predetermined drilling sample

Constructed-in sensors can present the system with real-time information on the surroundings. AI and laptop vision-powered techniques can use this enter to repeatedly determine doable hazards and examine the sample and dimension of drill holes. Or, to tell the actions of a distant human operator.

Primarily based on real-time information suggestions, the system may dynamically modify drilling habits if wanted.

These clever techniques sometimes use fuzzy logic-based controllers. Synthetic Neural Networks (ANNs) for predicting emulsion-based drilling fluid properties and the speed of penetration.

One other profit is that these machines could be operated remotely, minimizing the chance and enhancing security in incidents and severe accidents.

Utility 3: Predictive Upkeep

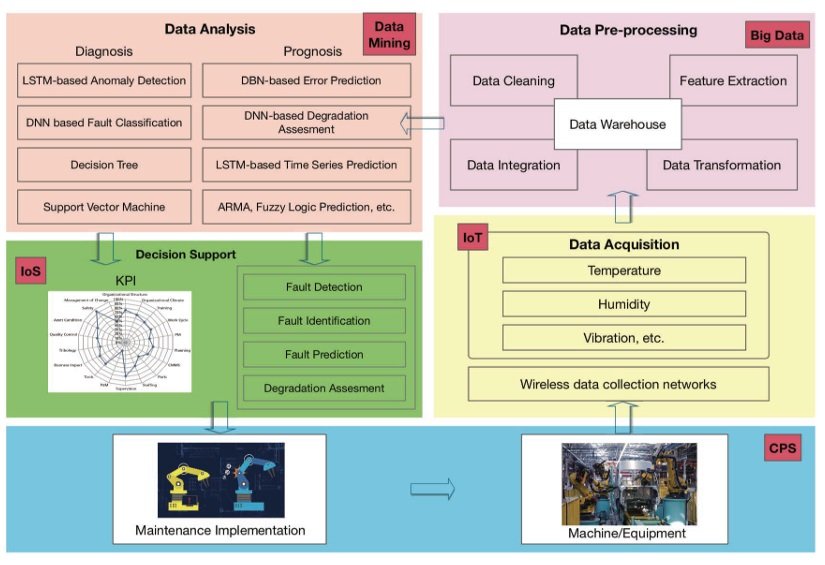

Mines face a steady battle to try to make their upkeep processes as environment friendly, cost-effective, and non-disruptive as doable. A typical mining operation oversees such an unlimited portfolio of infrastructure and tools that it’s nearly not possible to precisely and effectively monitor upkeep schedules utilizing typical strategies, like spreadsheets.

As in different industries, AI and ML algorithms can use mannequin specs and real-time tools efficiency to try to predict when upkeep will likely be wanted.

ML algorithms can analyze tools specs, service contracts, and real-time efficiency information to foretell failure charges or determine property that will require upkeep. This permits mines to hold out proactive upkeep or put together auxiliary tools prematurely.

Automating upkeep additionally helps in enhancing productiveness long-term as well timed upkeep interventions lengthen the lifespan of each fastened and cell property. And, as a bonus, better-functioning tools is safer for employees to function.

For instance, Vale, a Brazilian multinational metallic and mines company, makes use of predictive evaluation to assist save capital prices. They have been in a position to expand the lifespan of haul trucks by 30% and predict as much as 85% of rail breakdowns forward of time. Reportedly, predictive evaluation helps the corporate save as much as $7 million per 12 months.

Utility 4: Employee Security and Threat Evaluation

AI and ML applied sciences are already being deployed to assist guarantee employee security and the situations inside mines. Not solely does this assist mining operations reply shortly to speedy threats, however it additionally helps plan infrastructure to be extra resilient and safe.

One present resolution is utilizing AI-powered wearable IoT gadgets to watch the vitals of miners on shift, utilizing well being markers comparable to fatigue or bodily stress in actual time. Sensors put in on the positioning may shortly detect potential risks within the speedy surroundings, such because the presence of hazardous substances, excessive humidity, or excessive temperatures.

Different monitoring techniques can scan for environmental threat components, comparable to climate patterns, landslides, or different geological disasters.

Lastly, clever computing techniques can assist plan and execute mine operations extra safely. For instance, it’s doable to mannequin and predict roof or help collapse, flyrock, and blasting sample evaluation, water rush-in, subsidence threat, or goaf stability utilizing built-in CAD or 3D modeling software program.

Utility 5: Ore Sorting and Grade Management

As essentially the most engaging and easy-to-reach sources are exhausted, mines are combating declining high quality ranges. For instance, the ore quality in copper mining decreased by 25% in simply 10 years. AI and ML-based techniques can assist them optimize the standard of their current output, mitigating a number of the influence of this decline.

Utilizing AI expertise for dig-line optimization is nothing new, serving to mines get essentially the most out of a selected website. Extra superior techniques additionally assist miners analyze the potential worth of a website or ore deposit to plan or prioritize extraction.

Additional down the pipeline, AI-based sorting techniques are used to research huge quantities of waste rock and determine precious minerals in actual time. This not solely improves the restoration charge of the first materials but in addition that of secondary uncooked supplies. These techniques are extra correct and environment friendly than human sorters, with out the necessity for relaxation or shifts.

Utility 6: Robotics and Autonomous Automobiles

Drilling and blasting usually are not the one processes that could be automated with the assistance of clever computing. From drones to hauling vans to “robotic miners,” the mining business is more and more using autonomous applied sciences to carry out each mundane and harmful operations.

For instance, drones fitted with sensors and laptop imaginative and prescient applied sciences are already being deployed to survey websites from the air or present real-time monitoring. Some drones even use Mild Detection and Ranging (LiDAR) to create 3D maps of the surroundings, which could be helpful in figuring out transport corridors or stockpiling areas.

Automated haulage vans have additionally offered their value, particularly in open pit or floor mines the place haulage routes are sometimes restricted. These vans use AI algorithms to comply with pre-determined, optimum routes, typically over tough or harmful terrain. The identical clever techniques additionally formulate and comply with methods that optimize gas utilization and wait instances.

Innovators are growing swarm robotic mining techniques within the cutting-edge subject to handle excavation actions inside mines. These land-based “drones” use sensors and articulating robotic arms fitted with totally different tools to exchange the necessity for human miners successfully.

Offworld is one firm whose robotic mining techniques are set to debut in 2024. They envision a fleet of automated mining drones that work in unison, consisting of surveyors, excavators, collectors, haulers, and extra, utilizing the newest edge expertise. Working inside the mines themselves, these AI-enabled excavators and collectors will exchange a number of the most labor-intensive, probably hazardous, and life-threatening work inside mining operations.

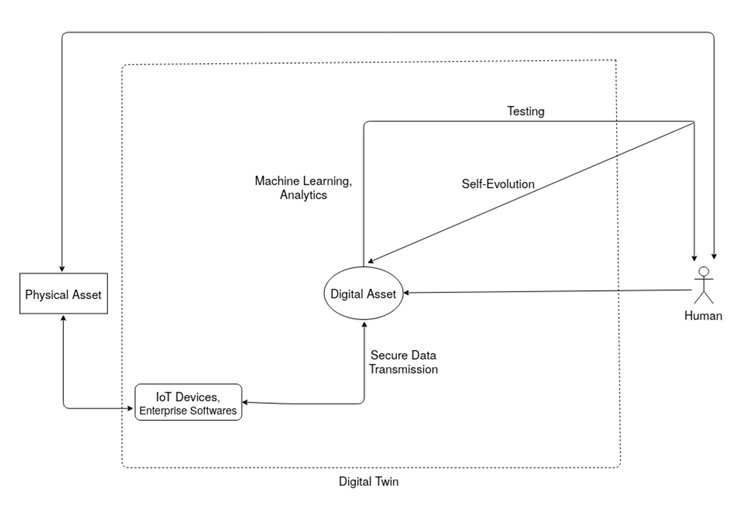

Utility 7: Digital Twinning

A digital twin is a digital mannequin of a bodily system that makes use of real-world information to run simulations and make predictions. Many industries already use digital twinning to simulate complicated real-world situations for testing, integration, monitoring, and upkeep.

Nevertheless, as a result of sheer scale and complexity of mining operations, the adoption of digital twins has but to select up velocity. That is set to alter with the huge developments made in AI, ML, and deep studying applied sciences over the previous few years.

Mines will quickly be capable of create and run full digital twins of particular person mining property or their total worldwide portfolio. This can open unprecedented alternatives to optimize mining operations at each scale and throughout each aspect, from exploration to working mining websites to managing your complete provide chain.

In brief, digital twins will improve mining firms’ capability with regard to:

- Modeling and simulating the habits and efficiency of mining property

- Stochastic mine planning and scheduling

- Optimize operations and predict failures

- Brief and long-term strategic decision-making

Quite a few mining organizations are already within the midst of planning and launching these so-called “good mines,” enabled by way of the usage of complete digital twinning expertise

The Way forward for AI in Mining

Rising environmental issues, useful resource depletion, and the rising demand for valuable minerals imply that the challenges going through the mining sector are more likely to persist. On the similar time, AI and ML proceed to evolve and show their value in a rising number of functions.

For instance, McKinsey estimates that the usage of AI will result in between $290-$390 billion in annual financial savings for these mining copper, iron ore, pure gasoline, coal, and crude oil by 2035. With these sorts of outcomes, the wedding between mining and clever computing applied sciences will doubtless develop into everlasting. In truth, it’s anticipated to achieve a market size of $18.96 billion by 2030, rising at a CAGR of 21.8% from simply $3.96 billion in 2022.

Learn extra about how Laptop Imaginative and prescient could be utilized in varied industries within the blogs under: